Every second, in every production line, hundreds of variables are constantly changing.

People and monitoring systems can record them, but today only a well-trained artificial intelligence can anticipate errors before they even occur.

At Gashor, we develop custom AI solutions that turn data into smart decisions: analyzing shape, color, size, weight, and critical levels — and automatically adjusting key parameters such as temperature, baking time, or line speed.

All of this happens without human intervention, resulting in less waste, less energy consumption, and greater sustainability.

Above all, it delivers total real-time control of your process.

From observation to anticipation

In the food industry, every variable matters. A minimal deviation in the mix, an out-of-range temperature, or a change in texture can affect the quality of the final product.

Until recently, controlling these factors depended on human expertise and systems that offered only a partial view. Today, artificial intelligence takes it further — analyzing, predicting, and acting in real time.

With Gashor AI, you can:

- Predict how your process will behave before a failure occurs.

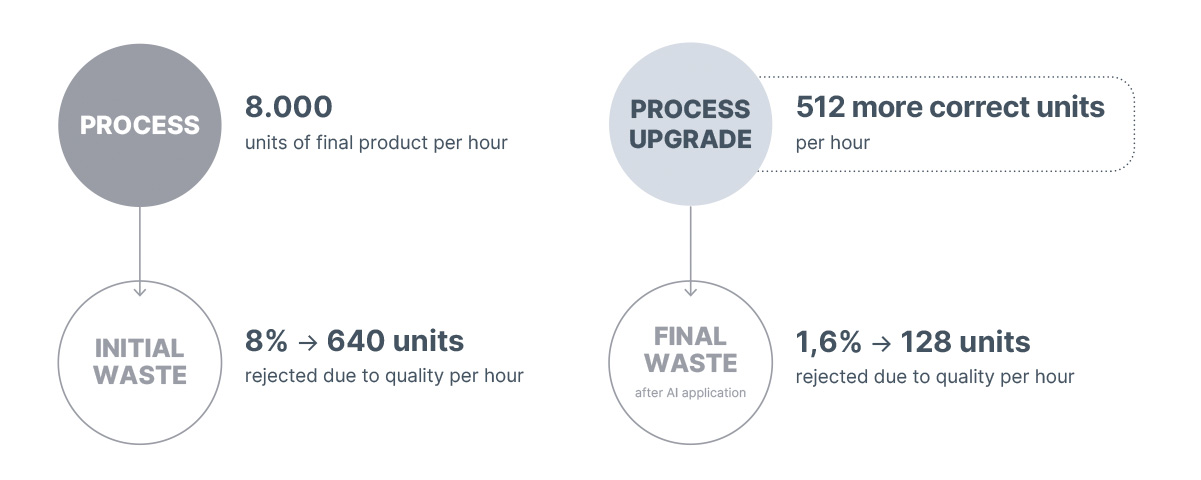

- Reduce waste by more than 80%.

- Control over 130 variables simultaneously.

- Detect errors before they affect production.

We’re not talking about intuition or estimates — we’re talking about decisions based on real data.

We design your own AI software, tailored to your process

There is no “universal software” for industrial production — at least, not in our view at Gashor.

Each plant, each recipe, and each objective is different. That’s why we develop AI solutions customized for each process, seamlessly integrated into your production line and adapted to your specific needs for quality, efficiency, and sustainability.

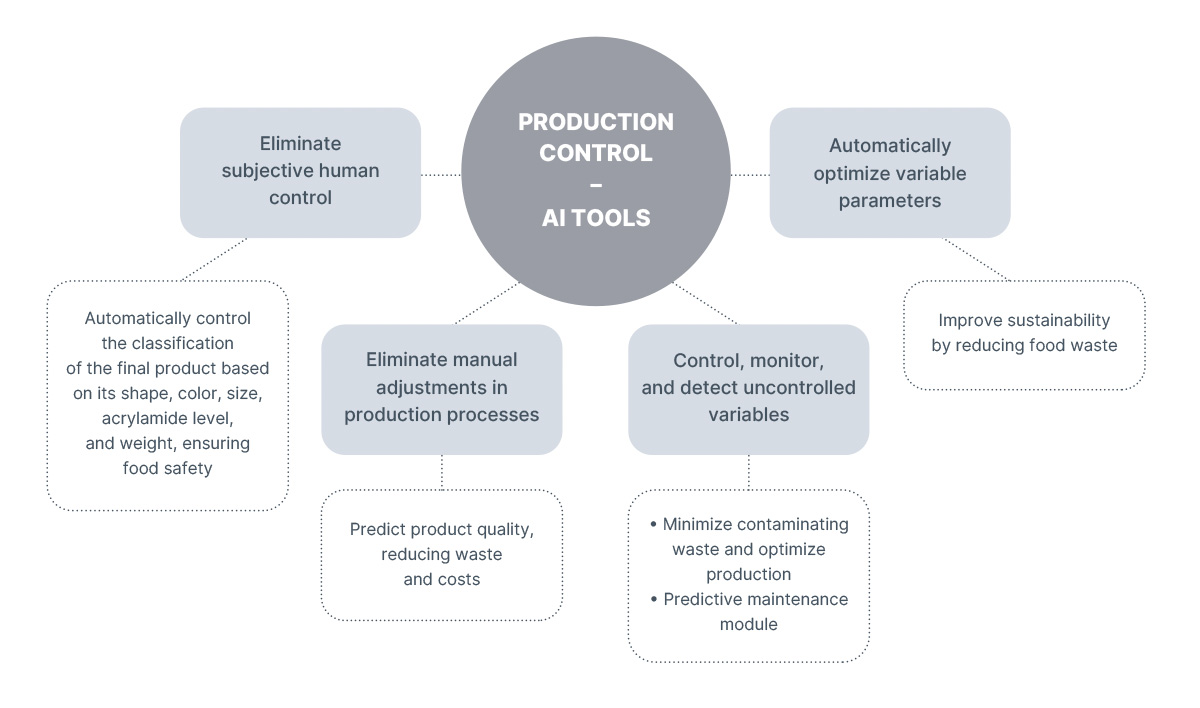

Our AI makes it possible to:

- Integrate predictive maintenance and troubleshooting.

- Detect and correct errors before they impact production.

- Automate critical decisions and eliminate subjectivity.

- Adjust parameters in real time without manual intervention.

- Reduce waste, energy consumption, and environmental impact.

- Control and classify the final product with objective criteria.

How Artificial Intelligence works in your plant

The key to our system is that it doesn’t just analyze — it acts, sending automatic commands based on predictions.

The Gashor AI software is modular and adapts to your line without disrupting its operation. Its workflow follows these steps:

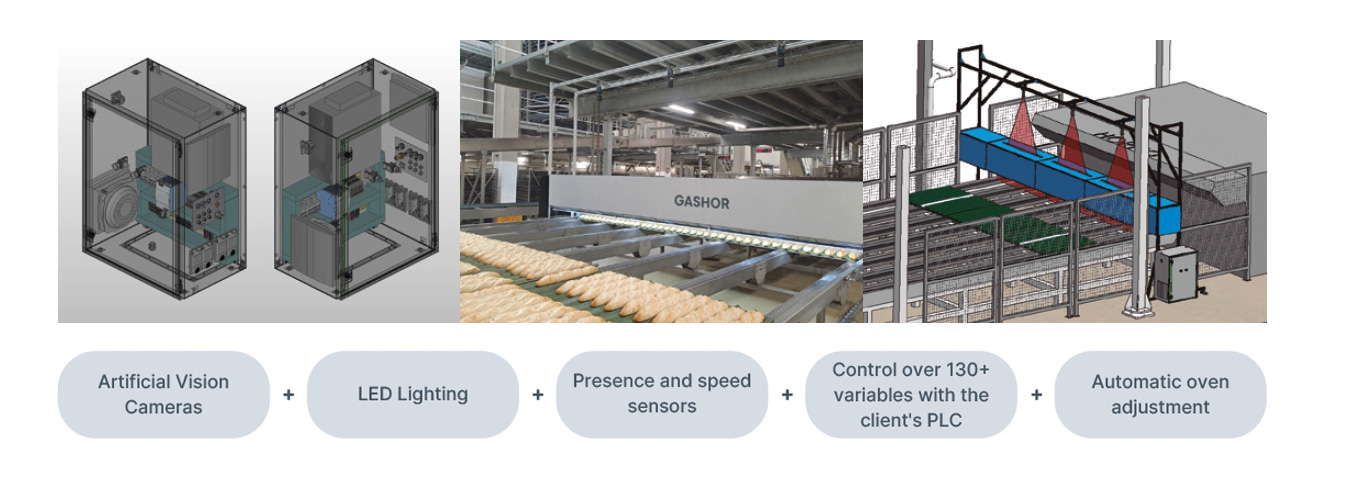

- Data capture: computer vision, sensors, and PLC readings.

- Predictive analysis: proprietary algorithms designed specifically for your process.

- Automatic action: equipment signals, real-time adjustments, and visible improvements.

And all this with maximum security guaranteed — your data belongs to you. Throughout the process, it remains stored on your own servers, never in the cloud.

More than technology: industry knowledge

Industrial AI works best when it understands its context. At Gashor, we’ve been supporting the industry for over 60 years — from food to chemical, pharmaceutical, cosmetic, and pet food sectors.

We know the key variables, downtime factors, and profitability goals. Our experience allows us to apply AI based on real plant operations, not just theory.

Moreover, AI can be integrated into any of Gashor’s business lines, designed to support you at every stage of your industrial project:

- Gashor Consulting: process diagnostics and analysis of critical variables to anticipate issues.

- Gashor Industry: design and manufacturing of equipment that interacts directly with AI.

- Gashor Innovation: development and customization of industrial AI software.

- Gashor Services: maintenance, audits, and ongoing support for intelligent systems.

Because artificial intelligence is not just a tool — it’s a catalyst that multiplies the effectiveness of your objectives.

Conclusion: making intelligence part of your daily operations

Industrial AI is no longer a future concept — it’s a tool that allows you to produce better, with less waste and more control.

At Gashor, we design intelligence from within the process, combining engineering, automation, industrial expertise…

… and human intelligence. That’s the key: never losing sight of the fact that we are people, working with people, creating products for people.

Want to discover how AI can be applied to your industrial process? Tell us about your project — we’ll show you how to tailor this technology to your goals.