In the food industry, ingredient temperature plays a crucial role in the quality of the final product. A key aspect in this regard is the temperature of the flour, which directly influences the dough’s properties and, therefore, the consistency, flavor, and texture of baked goods.

Without proper thermal control, temperature variations can affect process uniformity, increasing the risk of inconsistencies in production. Thermal variability can lead to problems such as:

- Changes in dough viscosity and elasticity.

- Irregularities in fermentation performance.

- Products with inconsistent characteristics between batches.

- Increased difficulties in production time management and raw material waste.

At Gashor, we put an end to this issue with our flour cooling system.

The solution: Gashor’s flour cooling system

At Gashor, we offer a flour cooling system specifically designed for the food industry.

This system cools flour to a constant and precise temperature, improving both process efficiency and final product quality.

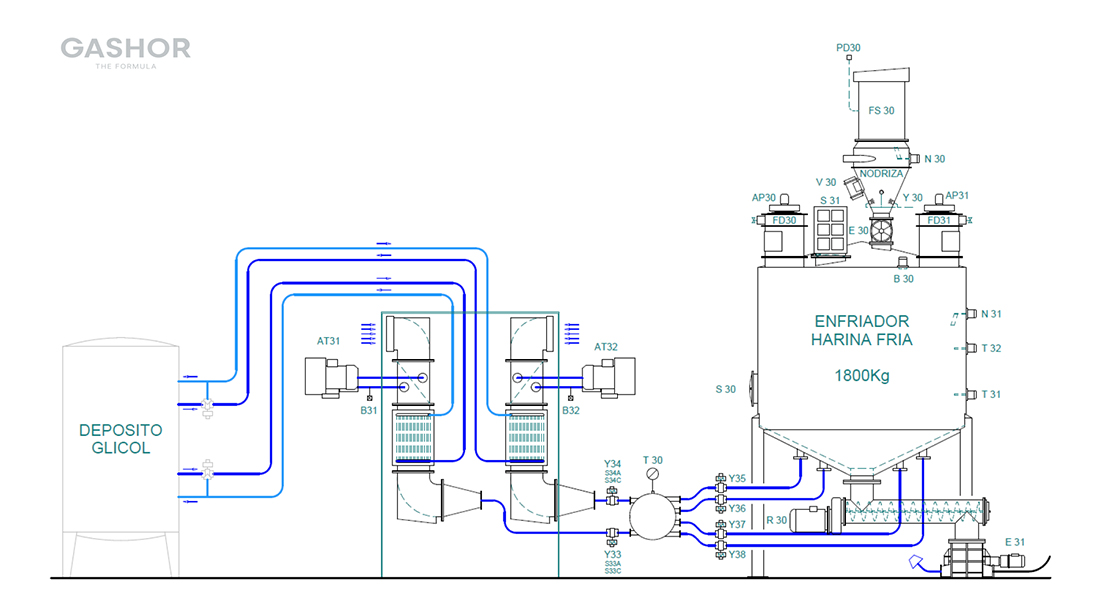

Our system operates through a glycol heat exchanger that generates cold air. This air continuously circulates through an intermediate tank, located between storage silos and the consumption point.

A high-pressure fan and a fluidized bed ensure that the flour mixes homogeneously with the cold air, maintaining a stable and uniform temperature at all times.

How we do it

We have perfected this process thanks to our in-depth knowledge of key stages in industrial ingredient management: storage, pneumatic transport, and dosing.

The Gashor flour cooling system is structured as follows:

- Flour Collection: Flour is transferred from the silos to an intermediate tank, where the cooling process begins.

- Cooling with Cold Air: A glycol heat exchanger generates cold air, which is introduced into the tank via a high-pressure fan.

- Homogeneous Mixing: Cold air circulates through the fluidized bed, ensuring that every flour particle reaches the desired temperature evenly.

- Temperature Control: A sensor monitors and regulates the temperature, ensuring that the flour leaves the system at the exact temperature required for production.

Advantages of Gashor’s flour cooling system

Compared to other systems that generate sudden and unstable temperature drops, our system provides significant benefits to achieve maximum product quality:

- Progressive and controlled temperature reduction, avoiding thermal shocks that could alter flour properties.

- Homogeneous cold distribution, thanks to direct action on every flour particle.

- Optimized energy efficiency, with an insulated and jacketed tankto prevent temperature loss and condensation.

- More controlled production and consistent quality, helping businesses maintain uniformity in their products.

- Precise temperature monitoring, with a sensor that regulates the heat exchangeraccording to each facility’s needs.

- Performance and adaptability customized to each requirement: Our systems can cool flour by up to 15°Cbelow its initial temperature, with a capacity of up to 2,400 kg/h.

In other words, we can design your own flour cooling system according to your specific refrigeration needs and consumption rates.

All while ensuring efficient and seamless integration into your production processes.

The risks of not controlling flour temperature

With over 60 years of experience in industrial ingredient management, we at Gashor have learned that lacking a proper flour cooling system can have serious consequences for food production.

Some of the most critical risks include:

- Fermentation failures: Improper temperatures affect the structure of bread and other baked goods.

- Reduced product shelf life: At the same time, poor thermal controlcan promote microorganism growth.

- Variability in dough texture: This issue complicates raw material handling, ultimately compromising final product quality.

This is why flour cooling is a key necessity for various food industry businesses, including:

- Industrial bakeries, which need dough with consistent texture and controlled fermentation.

- Biscuit and pastry manufacturers, where dough consistency directly impacts final product quality.

- Pasta manufacturers, where maintaining a stable flour temperature improves production and reduces quality fluctuations.

Failing to address these issues can directly impact a company’s profitability and brand reputation.

Gashor: take advantage of our expertise and commitment to the food industry

As experts in industrial ingredient management, Gashor offers turnkey solutions for storage, pneumatic transport, and micro-dosing.

Our deep understanding of the key points in the sector allows us to design systems that optimize production, reduce waste, and enhance product quality.

If you’re looking for an efficient solution for temperature control in your production process, our flour cooling system is the answer. Contact us and discover how we can help you optimize your operations.