In an industrial plant, what may seem like a minor detail can become the factor that brings everything to a halt.

A dosing motor, an electronic board, a critical valve — these are small components compared to the entire facility… but capable of stopping an entire production line for hours, days, or even weeks.

The consequences aren’t just technical. They’re economic, commercial, and often emotional. Because when production stops, customer orders don’t stop, market expectations don’t stop, and internal pressure to recover lost time doesn’t stop either.

And that can affect our stress levels, our team’s stress…

… and the company’s reputation.

That’s why at Gashor we see critical spare parts not as an expense, but as a strategic investment.

What happens when a spare part is missing at a critical moment

Anyone responsible for an industrial plant knows there’s no such thing as a small breakdown.

A failed part may seem insignificant… until it causes an entire line to stop. And when that happens, the impact escalates quickly.

It’s not just the machine that’s down.

It’s the plant manager watching orders stall and delivery deadlines get compromised.

It’s the maintenance chief racing against the clock, trying to find urgent — and often improvised — solutions.

It’s the purchasing department scrambling to get parts in hours, paying inflated prices and managing impossible deliveries.

Every minute without the right spare part means more tension, more cost, and more uncertainty.

What started as a technical issue becomes an organizational, commercial, and financial problem.

All because the critical spare part wasn’t available at the right time.

Strategy instead of improvisation

At Gashor, we know this well. It’s not about stocking parts randomly or trusting that “it’ll arrive when we need it.”

The key is designing a customized spare parts plan, tailored to each process, each plant, and each real risk.

This plan is based on a deep analysis of the facility: which parts are critical, which have long lead times, and which components are directly linked to essential assets.

This isn’t theoretical — it’s a risk and solution map that prevents a technical failure from turning into a crisis.

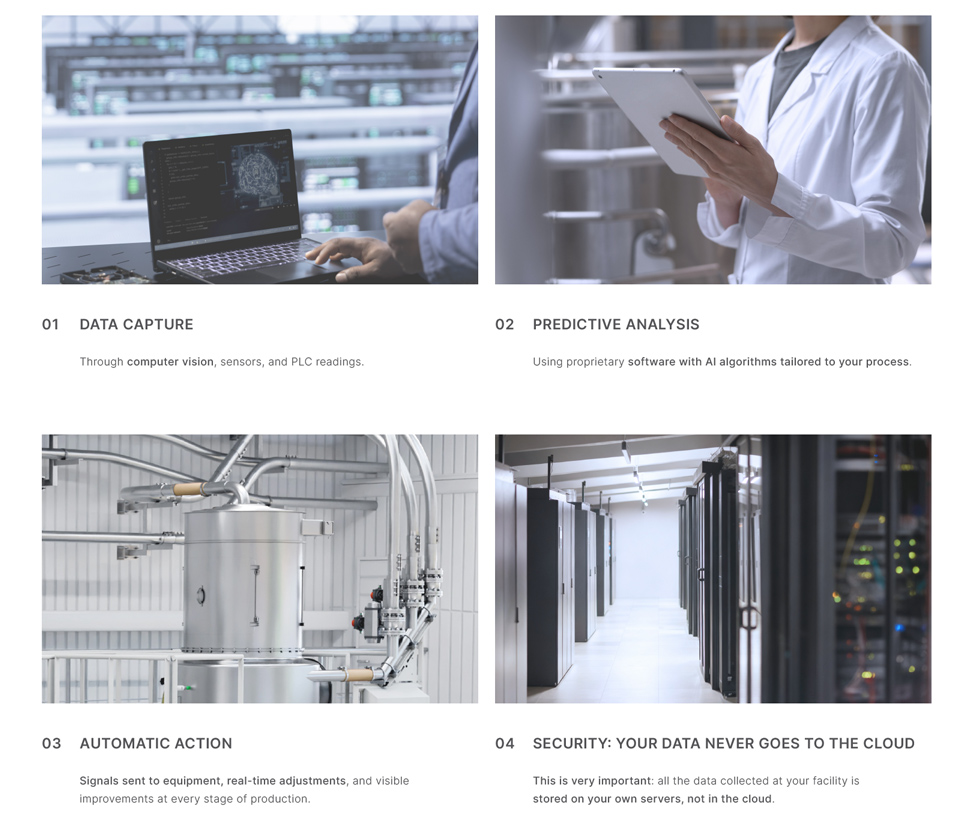

Artificial Intelligence: Predict before it happens

Creating a customized critical spare parts plan relies heavily on experience and knowledge. At Gashor, we’ve been helping industrial companies optimize their processes since 1959.

Today, however, thanks to Artificial Intelligence applied to process control, we can go one step further.

We’ve developed our own AI systems that allow us to anticipate failure patterns, predict wear, and calculate the exact moment when a part might become critical. This means we don’t just react better — we prevent issues using real data.

So, the spare parts plan isn’t static. It’s dynamic. It evolves with the plant itself, with production rhythms, with changes in ingredients, or with equipment behavior.

Contact us and we’ll tell you more.

An investment that shows in results

In short: when spare parts are treated as a strategic investment, the benefits are clear:

- Unplanned downtime is avoided.

- Maintenance pressure is reduced.

- Customer trust is reinforced by meeting deadlines.

- Brand reputation is protected.

- Business continuity is strengthened.

For decision-makers, it’s not just a technical issue — it’s a chance to bring tangible value to the organization, to be the link that prevents a setback from disrupting the entire chain.

The Gashor Formula: Stepping into our clients’ choes

As you can see, at Gashor we don’t just design storage, pneumatic transport, or dosing equipment. Our true value lies in supporting the customer throughout the entire lifecycle of their facility.

We always strive to think like our clients. To see beyond. To take the long view and act accordingly from the start.

Plus, we can support you at any stage of your project thanks to our four areas of expertise:

- Gashor Consulting: risk analysis and custom plan design

- Gashor Industry: robust, tailored equipment manufacturing

- Gashor Innovation: AI integration to anticipate failures and optimize decisions

- Gashor Services: technical support, audits, and immediate spare parts supply

A complete service structure, so every plant can work safely and with its own vision of the future.

Shall we talk about your spare parts plan?

Think about it: in an industrial plant, the question isn’t if a failure will happen — but when.

The difference lies in whether your plant will have the right spare part that day… or a production line at a standstill.

At Gashor, we can help you design a custom critical spare parts plan, backed by our engineers’ experience and AI-powered tools.

A plan that turns uncertainty into continuity, and improvisation into strategy.

Get in touch and discover how to protect your plant’s profitability and peace of mind with a tailor-made spare parts strategy.