Taking over the management of a new production plant or integrating a reused line often comes with a mix of excitement and vertigo. On paper, the numbers add up: the infrastructure exists, the silos are there, and the theoretical capacity is sufficient.

However, the day-to-day reality of the factory is usually far more stubborn than Excel.

Suddenly, you find yourself managing an installation you didn’t design, operating equipment that was conceived for a completely different production context — and that has now become your biggest bottleneck.

The ability to see beyond the problems

The symptoms are frustrating: pneumatic conveying that degrades the product due to excessive speed, blind spots where cleaning is impossible, or recurring blockages that disrupt production flow.

Faced with this scenario, the instinctive reaction is often drastic:

“This doesn’t work. We need to tear it down and build a new line.”

At Gashor, however, we believe demolition is often the easy way out. Real engineering means seeing value where others see only operational problems.

Today, we want to talk about industrial refurbishment — or how to transform a decontextualized installation into a profitable asset without starting from scratch.

The conflict is not the machine — it’s the parameter

When we audit an installation that a client considers “failed,” we rarely find unusable machinery. What we usually find are systems misaligned with the current product.

It’s very common to see lines originally designed for a robust product now struggling to process new recipes or more delicate ingredients.

- Pneumatic conveying does not usually fail because it is old, but because air velocity or line loading has not been readjusted to match the rheology of the new product.

- Dosing is not necessarily inaccurate due to wear, but because the control logic or screw pitch no longer aligns with the needs of your current recipe.

In these cases, the solution does not always involve buying new machinery. Often, a deep analysis allows the issue to be resolved through parameter adjustments, drive regulation, or minor PLC logic modifications.

We are not the typical company that tries to sell a brand-new installation at any cost. We want yours to work.

Industrial surgery: intervening only where it hurts

If, after analysis, parameter adjustments are not enough, we apply what we call “industrial surgery.”

But we don’t simply mean replacing one machine with a newer one. We mean functional reengineering: rethinking how the line operates while leveraging what you already have.

Sometimes, the intervention involves modifying the physics of the process (redesigning hopper geometry to prevent bridging or altering pneumatic layouts to smooth curves).

Other times, the “surgery” means rethinking how the process is controlled — for example, replacing the “brain” of the installation by integrating new weighing or dosing systems that better communicate with your existing PLC.

The objective is to preserve the valid structure (large silos, main piping, supports…) and operate only on the critical organs limiting performance. In doing so:

- We drastically reduce investment (CAPEX): You don’t pay for steel you already own.

● We minimize lost production: We avoid the long downtime required to dismantle an entire plant and build another.

● We correct the root problem: We don’t apply patches; we redefine how the line works for your current product.

Preparing your plant for the future (without throwing away the past)

Refurbishing is not patching — it’s updating technology. When we intervene in an old line, we don’t just repair mechanical flow.

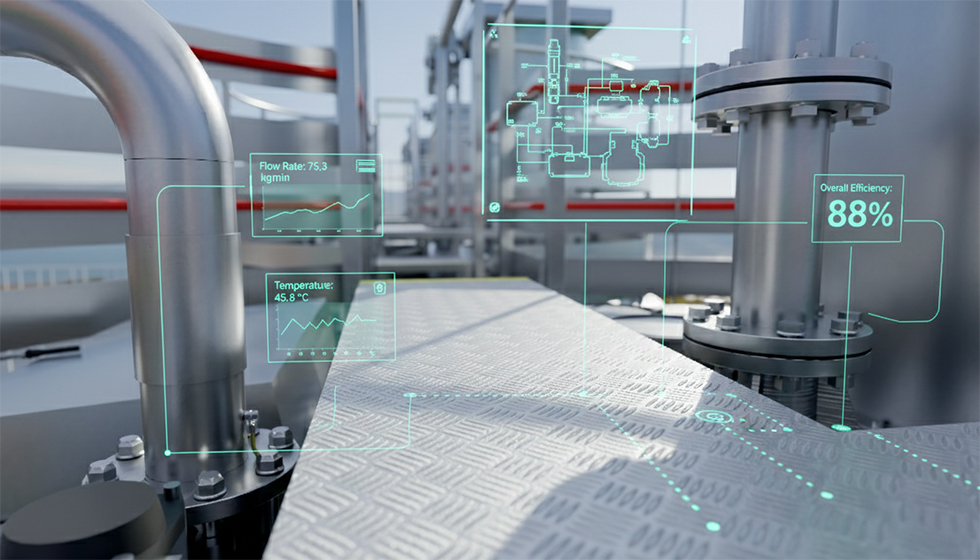

It’s the perfect opportunity to integrate modern control systems or even prepare the installation for Artificial Intelligence, allowing you to monitor variables that were previously invisible.

In short, inheriting a problematic installation does not have to be a sentence to inefficiency. It is an opportunity to demonstrate that, with the right engineering, you can achieve much more with what you already have.

If you’re dealing with a line that keeps you awake at night, before calling for demolition, call us.

Because your factory likely has much more future than it seems at first glance.

More than repairs: deep sector expertise

Industrial refurbishment works best when the entire plant context is understood — not just the machine that fails. At Gashor, we have spent more than 60 years supporting industry, from food to chemical, pharmaceutical, cosmetics, and pet food sectors.

We understand the variables that cause failures: product degradation due to friction, cleaning dead zones, and conveying bottlenecks.

Our experience allows us to apply precise “industrial surgery,” based on the reality of your factory — not standard catalog solutions.

Additionally, we can approach the recovery of your installation from every necessary angle, thanks to our four specialized divisions:

- Gashor Consulting: Auditing the existing line to identify which components to save and diagnosing the root cause of failures.

- Gashor Industry: Custom design and manufacturing of the new modules or equipment needed to fit perfectly into your current infrastructure.

- Gashor Innovation: Rheological studies and behavioural testing to ensure the new design corrects past flow or mixing issues.

- Gashor Services: Selective dismantling, assembly of new equipment, and rapid commissioning to minimize downtime.

Because refurbishing is not just about fixing what is broken — it’s about leveraging what you already have to multiply your operational efficiency.

Contact us and make your numbers work.