ARTIFICIAL INTELLIGENCE APPLIED TO THE FOOD INDUSTRY

Inicio Industrial artificial intelligence

At Gashor, we are experts in AI applied to the food industry: analyze your data, predict outcomes, reduce waste, and anticipate errors before they happen.

Optimize your processes in real time with computer vision and intelligent algorithms. No guesswork. No improvisation. Only data that guarantees the best results.

- Predict how your process will perform.

- Reduce waste by more than 80%.

- Monitor over 130 variables in real time.

- Detect failures before they occur.

All of this is now possible thanks to Gashor’s artificial intelligence, tailored for the food industry.

Your own custom AI software for your processes

At Gashor, we don’t develop generic Artificial Intelligence software — we design specific AI solutions for your processes, based on a deep understanding of your plant

Because we know that in your production line, what matters is not having more data, but turning it into precise decisions.

Get in touch with Gashor and we’ll show you how we do it using AI.

Gashor’s AI helps you detect and solve real process issues in record time

Our industrial AI tool allows you to:

Integrate predictive maintenance and troubleshooting into your processes.

Detect and correct errors before they impact product quality.

Automate critical decisions and eliminate subjective control.

Adjust parameters in real time without manual intervention.

Reduce waste, energy consumption, and pollutant emissions.

Control and classify the final product based on objective criteria.

See how we apply AI in your production plant

Gashor’s AI software isn’t a generic solution — it’s a modular development adaptable to your production line.

Here’s how we make it happen:

01

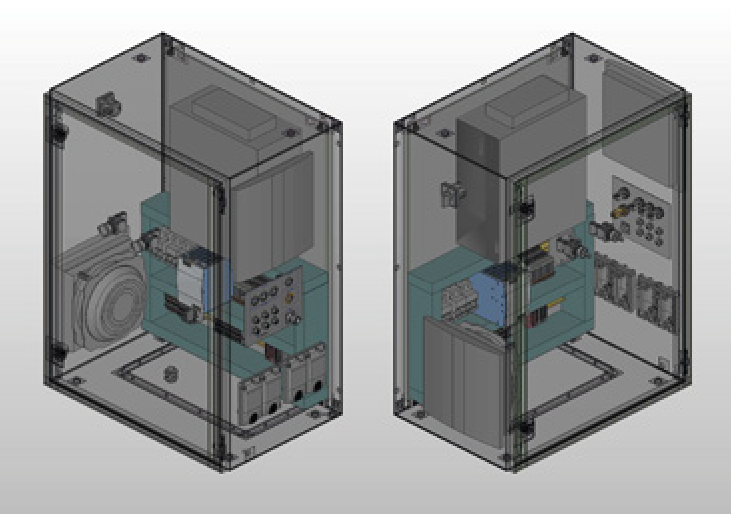

Data capture

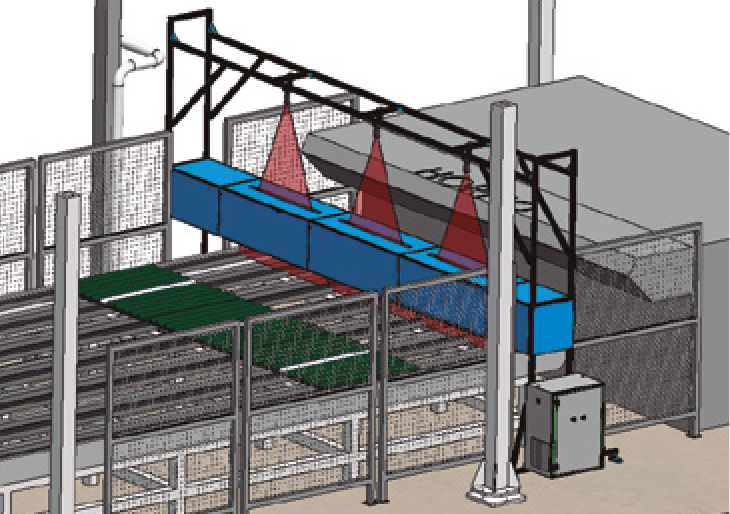

Through computer vision, sensors, and PLC readings.

02

Predictive analysis

Using proprietary software with AI algorithms tailored to your process.

03

Automatic action

Signals sent to equipment, real-time adjustments, and visible improvements at every stage of production.

04

Security: your data never goes to the cloud

This is very important: all the data collected at your facility is stored on your own servers, not in the cloud.

The key

The system doesn’t just analyze — it acts directly on the process, sending automatic commands based on predictions.

Success story: 80% waste reduction

An industrial line producing 8,000 units per hour had 8% of its products rejected due to quality issues. With our intelligent system, that rejection rate was reduced to 1.6%.

8.000

units/hour

640

units/hour (8%)

128

units/hour (1.6%)

512

additional usable units per hour

PRODUCTION

INITIAL WASTE

FINAL WASTE

IMPROVEMENT

Result: If 512 more units are recovered every hour, in an 8-hour shift that means over 4,000 additional units.

Success story: 80% waste reduction

An industrial line producing 8,000 units per hour had 8% of its products rejected due to quality issues. With our intelligent system, that rejection rate was reduced to 1.6%.

8.000

units/hour

PRODUCTION

640

units/hour (8%)

INITIAL WASTE

128

units/hour (1.6%)

FINAL WASTE

512

additional usable units per hour

IMPROVEMENT

Result: If 512 more units are recovered every hour, in an 8-hour shift that means over 4,000 additional units.

Industrial AI? Absolutely — but even better when it’s designed from within the industry

Gashor isn’t an IT company trying to understand the food industry. We are a technology company with over 60 years of experience improving various industrial sectors from the inside:

- Food industry

- Chemical industry

- Pharmaceutical industry

- Cosmetic industry

- Animal nutrition (pet food)

That’s why we understand your variables, your processes, your downtime, and your profitability goals.

And that’s why we know better than anyone how to optimize your processes — now, powered by Artificial Intelligence.

Discover the benefits of AI applied to your industrial process

Contact Gashor and tell us about your project. We’ll explain how to adapt it to your specific needs. Fill out the form and click SEND.